A Man for All Centuries

20th & 21st Centuries

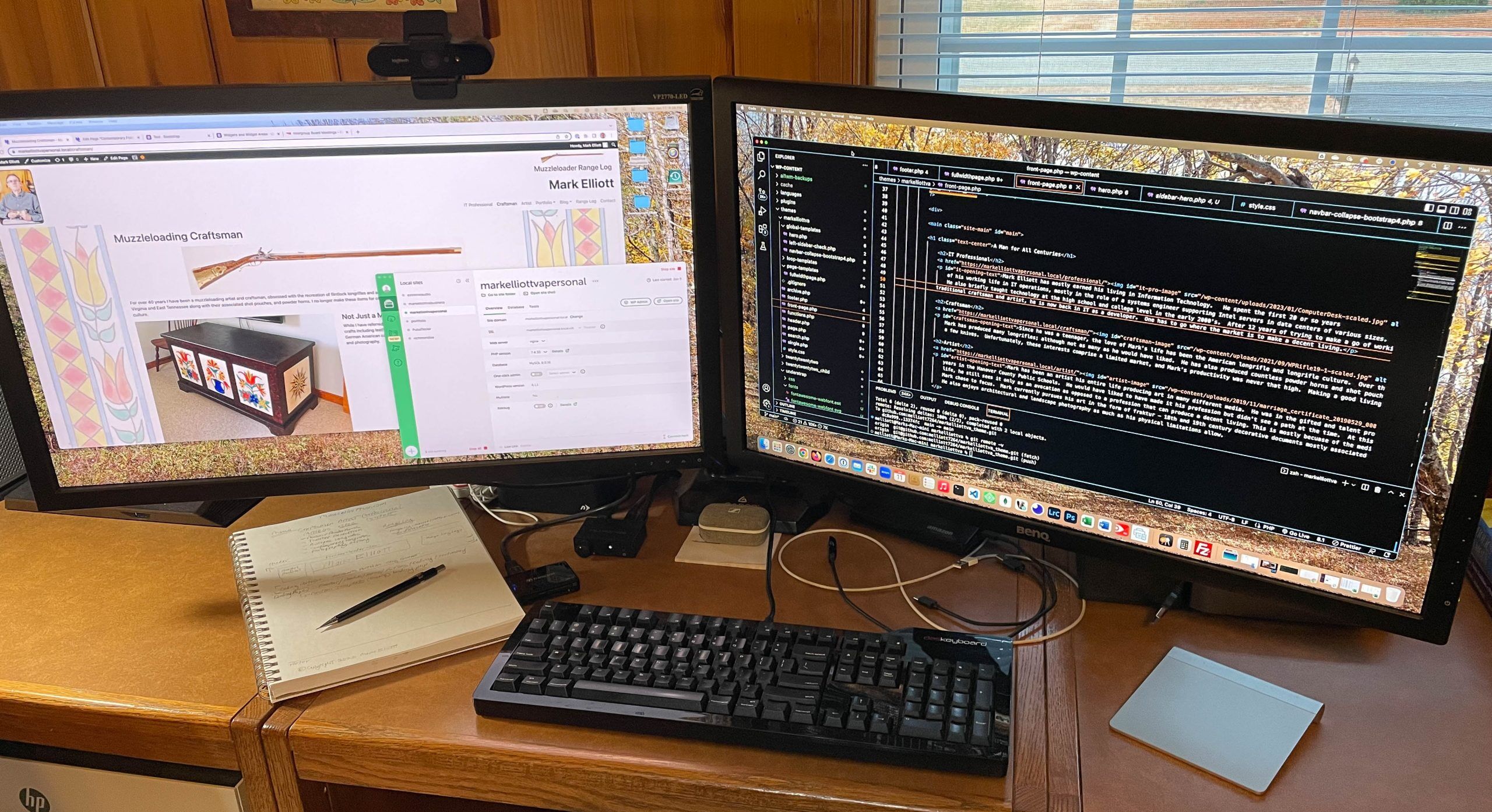

I have mostly earned my living in Information Technology, both in the 20th and 21st centuries. I have been coding since the early days of personal computers and spent the first 20 or so years of my working life in IT operations, mostly in the role of a systems engineer supporting Intel servers in data centers of various sizes. I also briefly taught technology at the high school and college level in the early 2000's. After 12 years of trying to make a go of working as a traditional craftsman and artist, I am now back in IT supporting multiple websites for a non-profit.

18th & 19th Centuries

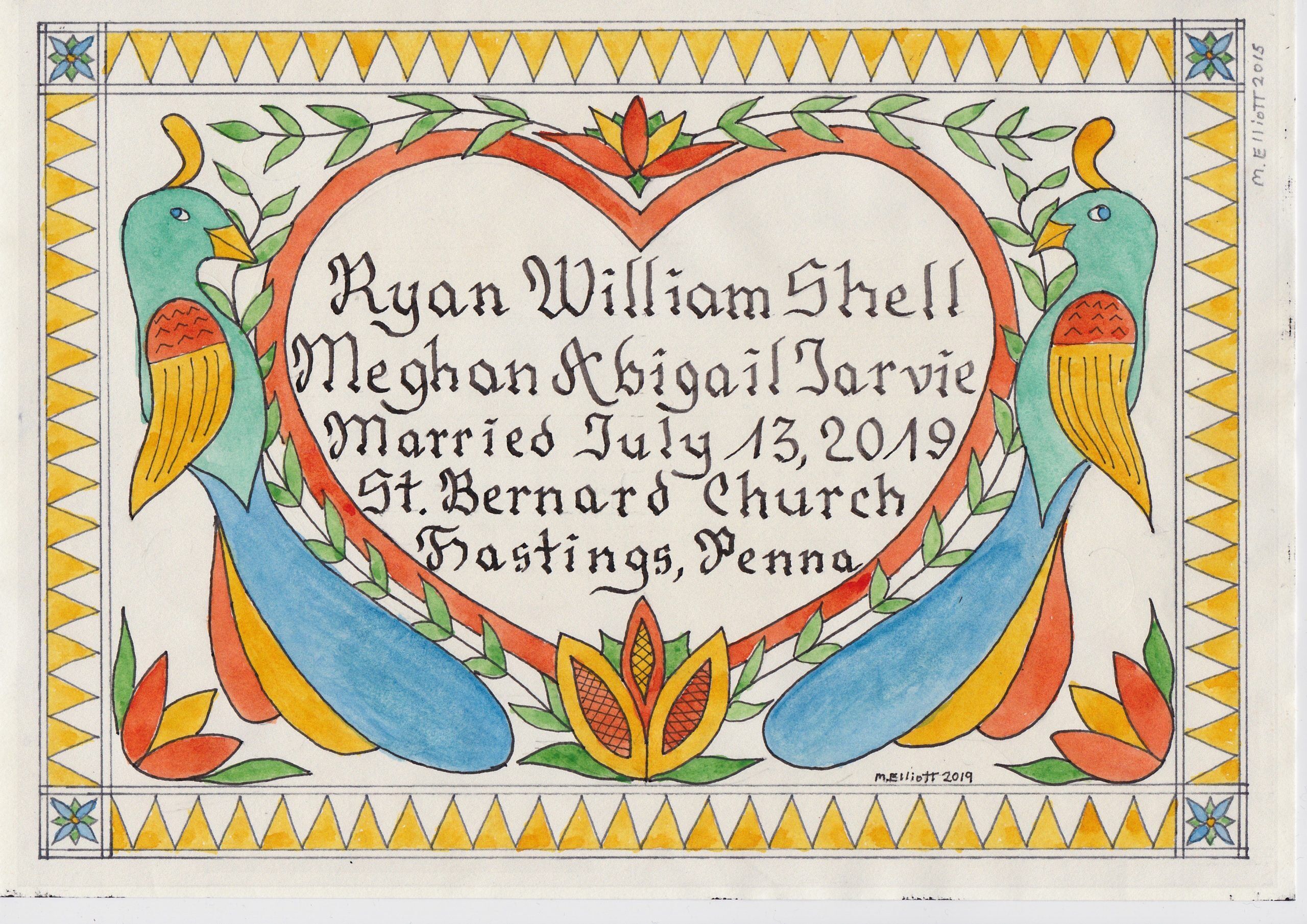

Since I was a teenager, the American longrifle and longrifle culture has held a special place in my heart. Over the years, I have produced many longrifles. I have also produced countless powder horns and shot pouches as well as a few knives. After a number of years trying to make a living practicing my traditional crafts, I am now pursuing it just as a hobby.